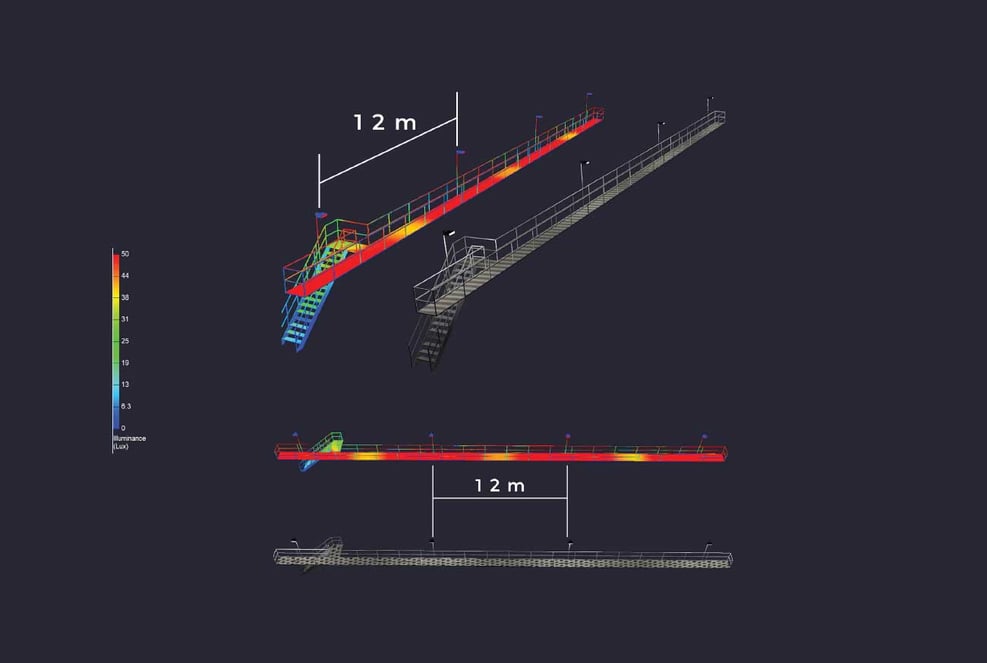

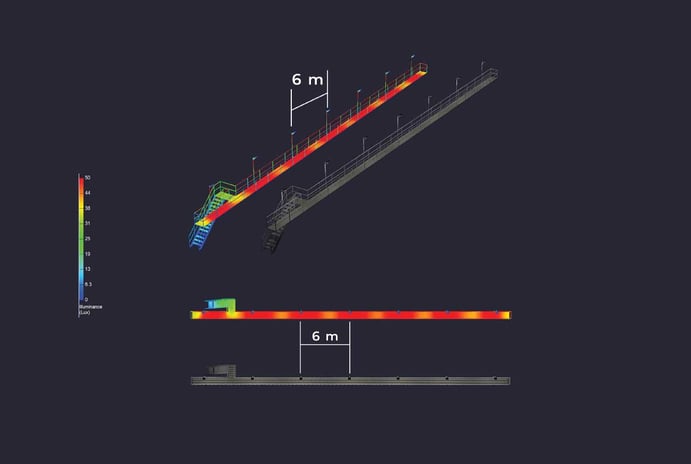

Nemalux lights allow for a pole spacing of 12m on the center. This spacing doubles the distance compared to conventional walkway lights.

Conventional lights often need improving for industrial walkways and platforms.

They deliver high contrast ratios between poles, resulting in poor visibility. Poor optical control forces the installation of more fixtures and support structures. These poles often mandate a 25° or 45° tilt.

HID fixtures generally have a high maintenance cost and consume up to 100% more power per fixture.

Furthermore, bulbs remain susceptible to vibration and experience premature failure.

Download our 1-page PDF use case to share

Install up to 50% fewer Nemalux lights on walkways utilizing superior optics and a range of beams. Nemalux fixtures distribute light 12 meters, double that of conventional fixtures.

Nemalux's JR, MR and XR models offer superior performance in a convenient package.

Fewer fixtures illuminate in longer sections using type 1 or 2 distribution patterns. Conducting a one-to-one replacement still reduces power consumption by over 50%. Slip fitters and other mounting options support retrofit and new projects.

Turnkey pole assemblies reduce installation time for new projects. JR, MR and XR allow the through-wiring of fixtures on a single circuit. 100% field serviceable components extend system life and reduce life cycle costs.

High-output, optically-controlled LED lights:

- Models ranging from 3,000 to 20,000 lumens

- Mounting heights of 8' - 25'

- Suitable for harsh and hazardous locations

- IDA - Dark Sky certified variants are available

- Class I Division 2 I Class II Division 2 I Zone 21 (XR) ratings

Nemalux LED lights provide enhanced safety on industrial walkways, catwalks & platforms. Our luminaires reduce maintenance and total lifecycle costs. Our fixtures are more energy-efficient than legacy HPS or MH fixtures. Making Nemalux a great lighting replacement option for conventional walkway lights. Our lighting design services can support project implementation and improve outcomes.