Simplified Installation & Operation

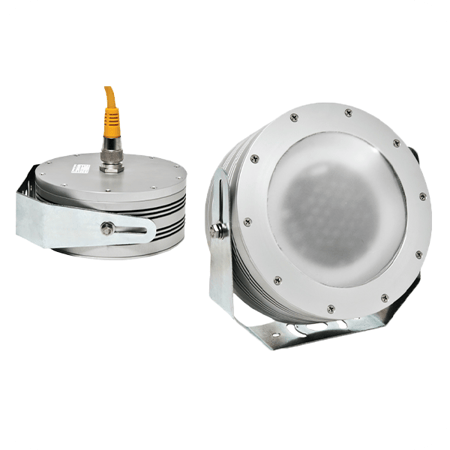

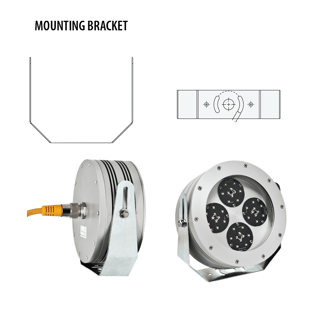

The XCANLED requires an external junction box for field wiring. Which allows termination to the main 12 or 24 Volt DC line. The pre-wired cable options and yoke mount allow for installation and aiming flexibility.

Locations that use solar power can connect the XCANLED without the need for inverters. The XCANLED operates on 12 to 24 Volt DC and eliminates the need to convert to AC power. Maintaining low-voltage DC operations throughout the system maximizes efficiency and reduces costs.

Military and aerospace customers use custom variants of the XCANLED. Exposure to high vibration, controlled rocket engine combustion, and momentary heat is common. Protective options include an IR-reflective glass lens and heavy-duty surface brackets. Specialty linear drivers allow flicker-free operation for high-speed camera vision.