Industrial LED Lighting Design

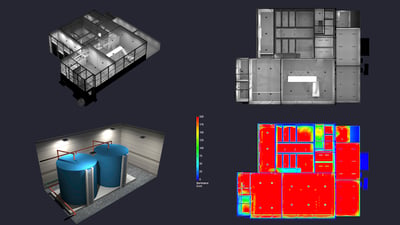

We provide design support for explosion proof and hazardous location lighting projects. Nemalux conducts layouts using AGI32 and Dialux Evo software packages.

Facility Lighting Audits

Nemalux offers complimentary lighting audit services for industrial, municipal, marine, and hazardous sites.

Custom Luminaire Fabrication

Projects may demand unique solutions to address site-specific challenges. Our in-house product development team offers custom mounting and other add-on options.

Lighting Performance Comparison

Assessing legacy light fixtures allows us to present suitable LED luminaires. Projects requiring a one-to-one replacement approach, use, or performance mapping service.

OEM Fixture Design

Corporations needing specific solutions use Nemalux's design and contract manufacturing service. Such solutions are unique to each customer and remain exclusive to their brands.

Kitting & Pre-Assembly Service

Remote projects needing quick installation options use supplemental services from Nemalux. Pre-installed hardware and wiring on our lights, save time and reduce labor costs.

We provide complimentary Lighting Designs for industrial applications.

Lighting Design is critical to address safety issues on site. Nemalux provides unparalleled customer service to manage your lighting requirements. We offer luminaires that improve safety, decrease environmental impacts, and increase operational efficiency. We offer exceptional services that provide solutions to your illumination projects.