Luminaire Case Design

Nemalux uses marine-grade aluminum alloys with low copper content (copper-free) luminaire housings. They withstand long-term exposure to chemicals and salt water and are effective heatsinks. Powder coating and anodizing options further improve housing performance in rugged environments. Specialty powder coats and processes provide a mil-spec-compliant multi-layer finish. This coating withstands simultaneous exposure to corrosive chemicals, UV, and saltwater. Nemalux designs luminaire cases around the specific requirements of LED technology. They are improving safety while avoiding retrofits of legacy technology enclosures.

Vented Light Enclosures

Industrial enclosures experience vast exposure to the surrounding atmosphere, temperature, and humidity. Nemalux fixtures use pressure equalization vents for ingress protection of IP66/67/68. These protect and seal our luminaires while allowing the system to breathe. Benefits of IP rated lights dissipate excess humidity and reduce stress on components. The vented light enclosure avoids the buildup of droplets on sensitive electronics.

Luminaire Mounting Hardware

The use of flexible mounting hardware is instrumental for an optimized installation process. Industrial grade bracket designs withstand severe vibration, impact, and chemical exposure. Our fixtures also offer secondary safety points to fall protection. Optimized placement in new and existing facilities reduces costs and deployment time. Our mounting catalog includes an extensive range of brackets for specific fixture series. This feature lowers luminaire types on the final bill of material. It also streamlines the engineering, procurement, installation, and maintenance process. A significant competitive advantage in our addressable market segment.

LED Lighting

Nemalux selects high-quality diodes from CREE, Samsung, and Nichia. We underpower the diodes to reduce heat stress and premature aging of components. Reduced 50-70% current flow of the rated max value extends the longevity of the LEDs. This extended longevity allows for implementation in harsh and hazardous environments.

Metal Core Printed Circuit Boards (MCPCB)

MCPCBs are vital for heat transfer from the LEDs to the external case. These circuit boards increase temperature range and extend performance in industrial applications. Built-in redundancies account for a possible failure of individual diodes. This feature permits continuous operation and minimal change in the overall light output. The serviceability of our lights allows for future upgrades and field replacements. This attribute is a significant benefit. Our designs offer easy access to light engines and solder-free quick-connect components.

Secondary Optics

The secondary optics location on our fixtures is behind the external protective lens. We use LEDiL optics for flexibility during the lighting design and application process. Such devices shape the light, reducing installation and operation costs. AGI32 and Dialux Evo design software incorporate LEDiL with our lighting designs. The combination provides projects and facility's designs with optimal spacing and mounting heights.

Power Supplies

Programmable HazLoc power supplies balance the approach between thermal management and efficiency. 0-10V dimmable power supplies are available for modifying illumination levels. L90 values are essential indicators of the overall system's reliability. Carefully consider L90 values during the luminaire selection process. In high-output systems, the use of multiple power supplies creates functional reliability. A portion of LEDs can still function on the fixture in case of an individual power supply failure.

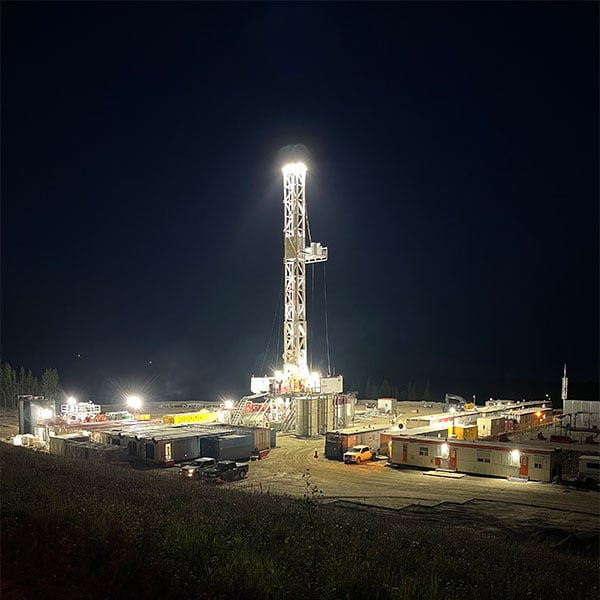

Glare Reduction

Safety on industrial sites decreases from inadequate illumination, excessive glare, and light trespass. The appropriate fixture needs the correct mounting height, tilting angle, and lens type. A glare-reduction lens and sharp cutoff improve visual comfort and acuity. These factors with our fixtures have substantial impacts on eliminating glare.

Serviceability

A Nemalux field serviceable light fixture has replaceable components for onsite use. Conventional HID lights have service in mind, too. Yet, it is due to the shorter life expectancy of bulbs and ballasts. The emergence of LED technology has caused a shift to non-serviceable/sealed systems. This outdated approach from other LED manufacturers gives similarities to HIDs lights. In this scope, valuable fixtures become obsolete and need replacing. The Nemalux luminaire design always has field serviceability in mind. This design feature allows maintenance and upgrading options outside the warranty period. A much more cost and environmentally-effective approach to changing aging components.